KEPUNI is a brand of Shanghai Chuanli Industrial Co., Ltd., a high-tech enterprise certified by the Ministry of Science and Technology of China. It integrates R&D, production, sales and after-sales service.

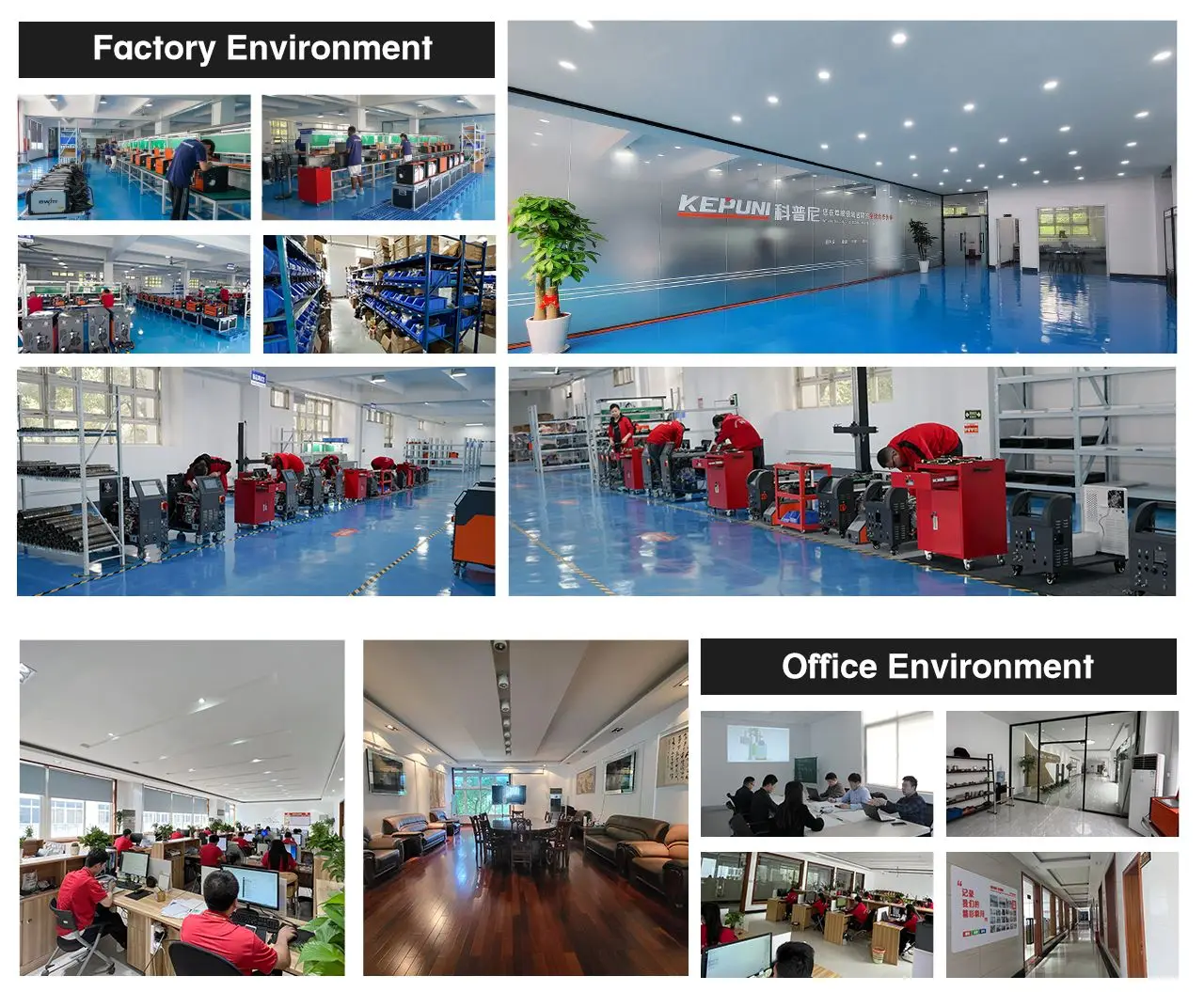

The company is headquartered in Shanghai, the international metropolis, which is 15-minute drive to Hongqiao Airport and High-Speed Railway Station. The company has a production park of 10 thousand m2 with 280 colleagues working in it, including 36 experts in R&D. The subsidiaries scatter widely in the cities of Tianjin, Guangzhou, Chongqing and the provinces of Anhui, Jiangsu etc. The products are supplied broadly in the five continents around the world through the sales agents and distributors in Europe, Asia and South America.

The company’s core R&D team occupies a 20-year experience in the field of professional welding, professional power supply, pipeline welding and its automation. We are committed to providing our customers with reliable quality and environmentally friendly products. The company has independent capability of R&D, production, sales and after-sales service in closed orbital welding heads, open orbital welding heads, tube to tube sheet welding head, cold welding machine, orbital cutting machine, tube facing machine, hand held laser welding machine, ultrasonic metal-welding machine and others. All customers and potential partners are welcome to visit us.

Ms. Sun, the General Manager, lived in a working family in 1980s, where her father worked as a welder without any protection and supported the family with a meager salary. Since she was a child, the dream seed, that is to change the welding methods, to simplify the welding operations, to create cleaner welding environment through technological endeavors in the future, germinated in her heart. After the graduation from university, Ms Sun has been engaged in the R&D of welding machines for years. In 2011, she and her team founded the KEPUNI welder brand in Shanghai and developed China’s first welder-friendly protection for welders that reduced radiation to human body. The sales of this innovative product was a great success at the 12th China International Industrial Fair (CIIF) in 2012. The R&D of KEPUNI is oriented towards automation, human protection and environmental protection. The company’s business philosophy is employee-centric and all employees share the fruits of the company's development.

In addition to the standardized 8-hour 5-day working system and full payment of social insurance, the company also provides employees the following benefits:

1. Setting up a gym, a children's playground and employee entertainment facilities in order to care for the physical and mental health of employees;

2. The establishment of a company relief fund to provide accident protection for company employees and their families. So far, more than 300 people have been helped with more than 800 thousand US dollars;

3. Setting up a dowry model to provide a bonus to outstanding employees who have worked in the company for a certain number of years and voluntarily leave for another personal development, in order to thank their contribution to the company;

4. In China's welding industry, being the first to introduce the lifelong employment system to support the employees in old age and ensure their financial status in all their life;

5. In terms of psychological care, the company offers employees and their immediate family members the benefit of a free seven-day domestic trip every year;

6. For outstanding employees of more than two years, the opportunity to become limited partners of the company and enjoy the profit dividends.

R&D: As to environmental protection, the company has always been insisting on solving problems from the source of R&D. The concept of environmental protection is implanted in the the welding products during the R&D, production and use in the whole life cycle, no matter they are products of orbital welding, cold welding, laser welding or ultrasonic welding, whose direction is towards the radiation reduction to human body and the pollution reduction in operating environments, for example, with PFC technology used in welding power supply, high-frequency electronic arc-starting technology and visual welding solutions for long-distance or external operations.

Production: Based on the concept of garbage classification and recycling, producing materials are reused as much as possible. Every month, the environmental star selection is held among the employees to improve their awareness of environmental protection.

Use: Thanks to innovative products that reduce pollution, welders can operate in clean overalls, reducing secondary environmental pollution caused by daily messes.

1. Strictly implementing the payments to suppliers and keep zero arrears;

2. Reviewing the quality system and environmental protection;

3. Strictly prohibiting the occurrence of welfare deduction and employee mistreatment;

4. Welcome global suppliers to provide us with parts, contact: info@kepuni.com

5. Welcome global partners and customers to point out the environment-unfriendly aspect or potential employee mistreatment in our work to us, contact: quality@kepuni.com

1. Our internal processes refer to automotive quality management tools such as APQP, PPAD, FMEA and 8-D reports;

2. Our Department of Quality evaluates all employees involved in product quality every month and hold quality star assessment, rewarding the good ones;

3. ISO9001 quality system certification and ISO14001 environmental management system certification conducted by external professional certification entities every year;

4. ISO45001 career health and safety management system certification conducted every year;

5. CE certification of EU conducted for all products;

6. Barcode filing system established for all parts and components, traceable to their production, sales and after-sales service.

1. Establishing a global after-sales network gradually;

2. Promising the customers a eight-year supply service of spare parts for the sold products since the sale date;

3. Response time of after-sales service within 2 hours, solution proposed within 8 hours;

4. Durative training of English-speaking global after-sales engineers, available to conduct barrier-free communication with customers;

5. Some current products upgraded to Internet of Things (IoT) technology now, and all products upgraded to IoT technology in 2025, to ensure the timeliness and convenience of application updating and after-sales service.